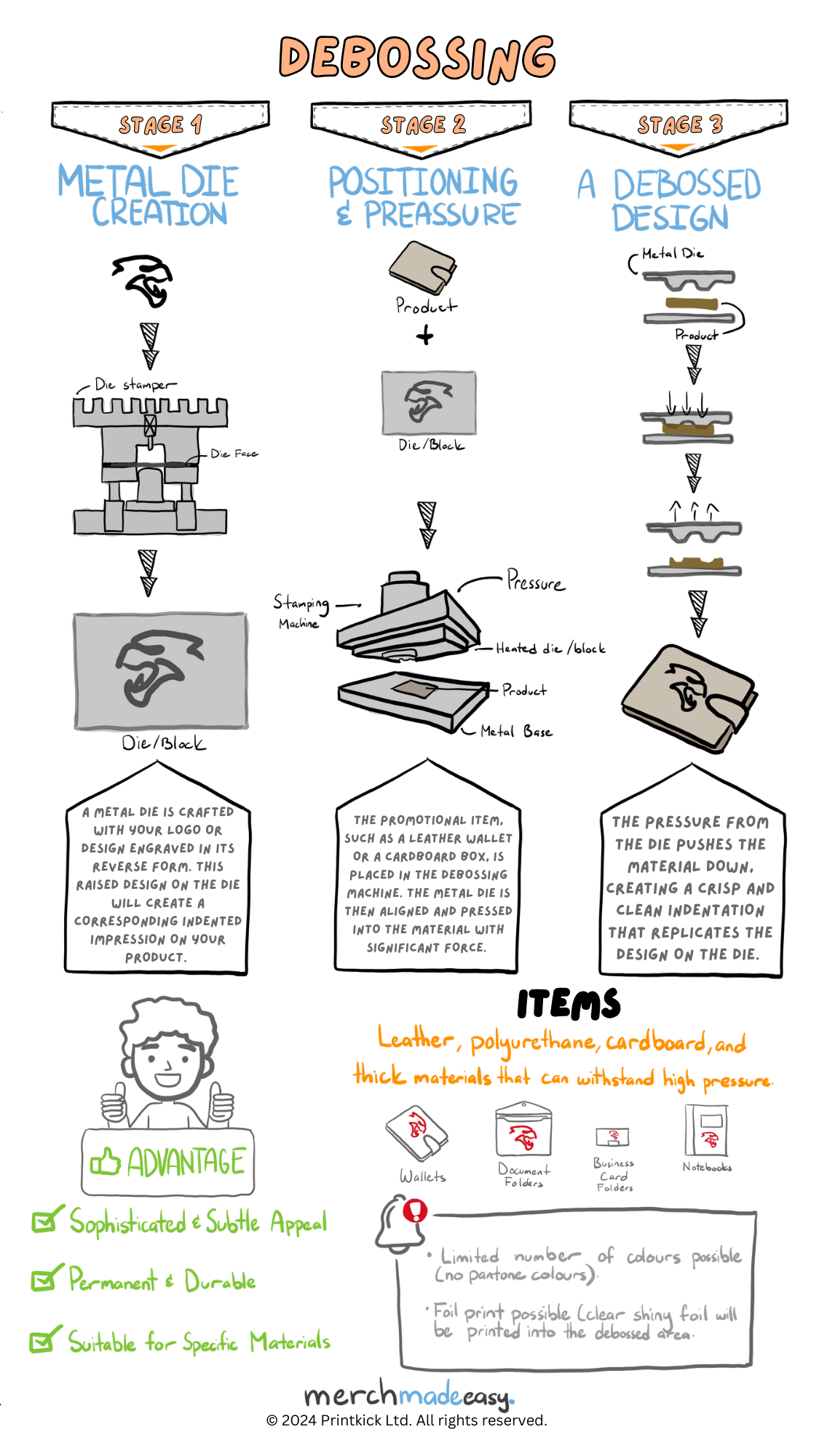

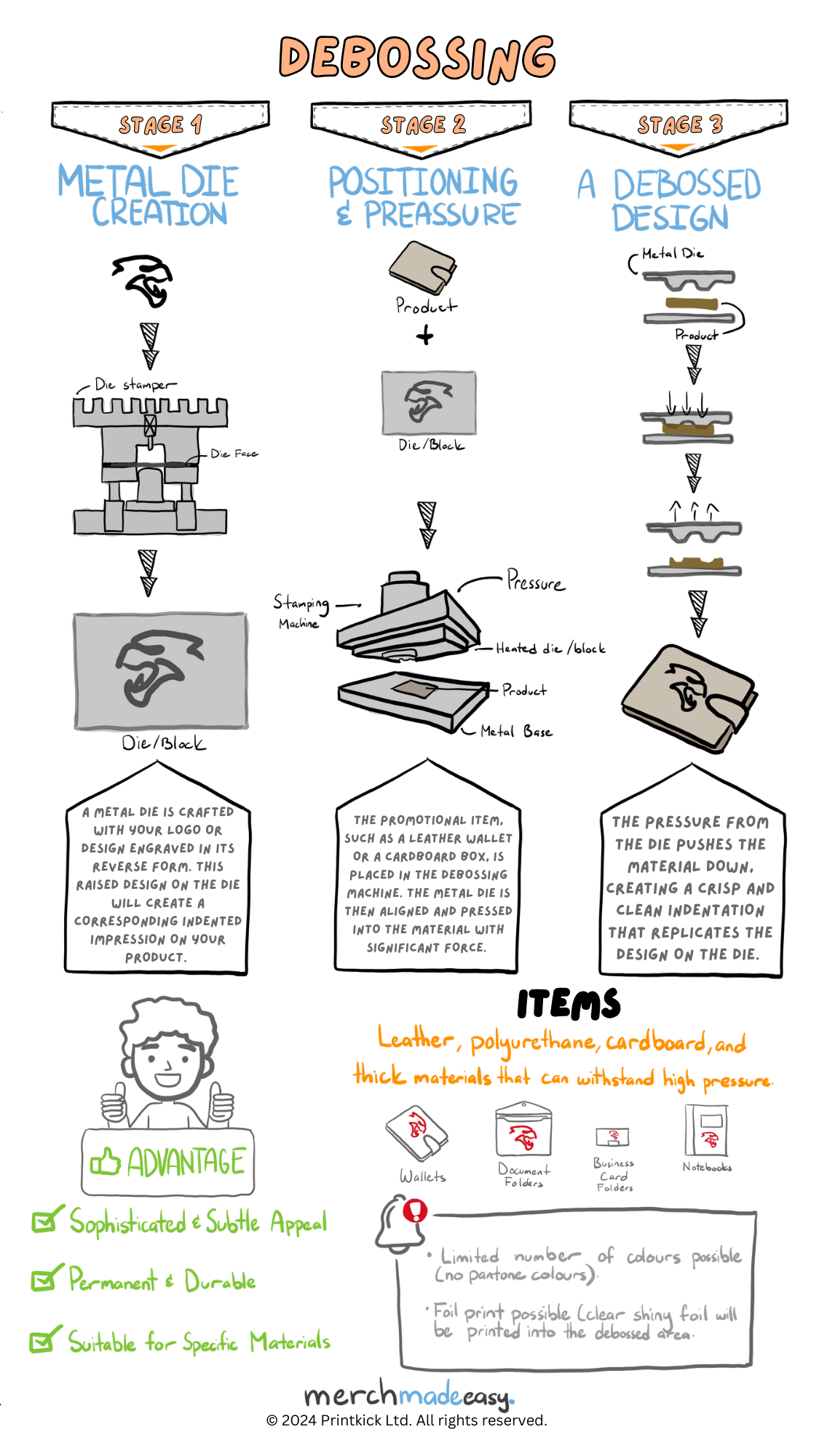

How Does Debossing Work?

Promo Store offers a range of personalization techniques, and debossing stands out for its ability to create sophisticated, indented designs on a variety of materials. This technique is particularly popular for leather, PU (polyurethane), and cardboard products.

Debossing creates a subtle yet elegant impression of your logo or design. Here's a look at the process:

- Metal Die Creation: A metal die is crafted with your logo or design engraved in its reverse form. This raised design on the die will create a corresponding indented impression on your product.

- Positioning & Pressure: The promotional item, such as a leather wallet or a cardboard box, is placed in the debossing machine. The metal die is then aligned and pressed into the material with significant force.

- A Debossed Design: The pressure from the die pushes the material down, creating a crisp and clean indentation that replicates the design on the die.

Why Choose Debossing for Promo Merch?

- Sophisticated & Subtle Appeal: Debossing offers a refined and understated look, ideal for adding a touch of class to leather products, packaging, and more

- Permanent & Durable: The debossed impression is permanent, creating a long-lasting and elegant mark that won't fade or peel over time.

- Suitable for Specific Materials: Debossing works best on thicker materials like leather, PU, and cardboard that can withstand the high pressure required for creating the indented design. Additionally, the surface should be flat and even for optimal result

Items

- Document folders

- Wallets

- Business card folders

- Notebooks

Good to know

- Limited number of colours possible (no pantone colours)

- Foil print possible (clear shiny Foil will be printed into the debossed area)