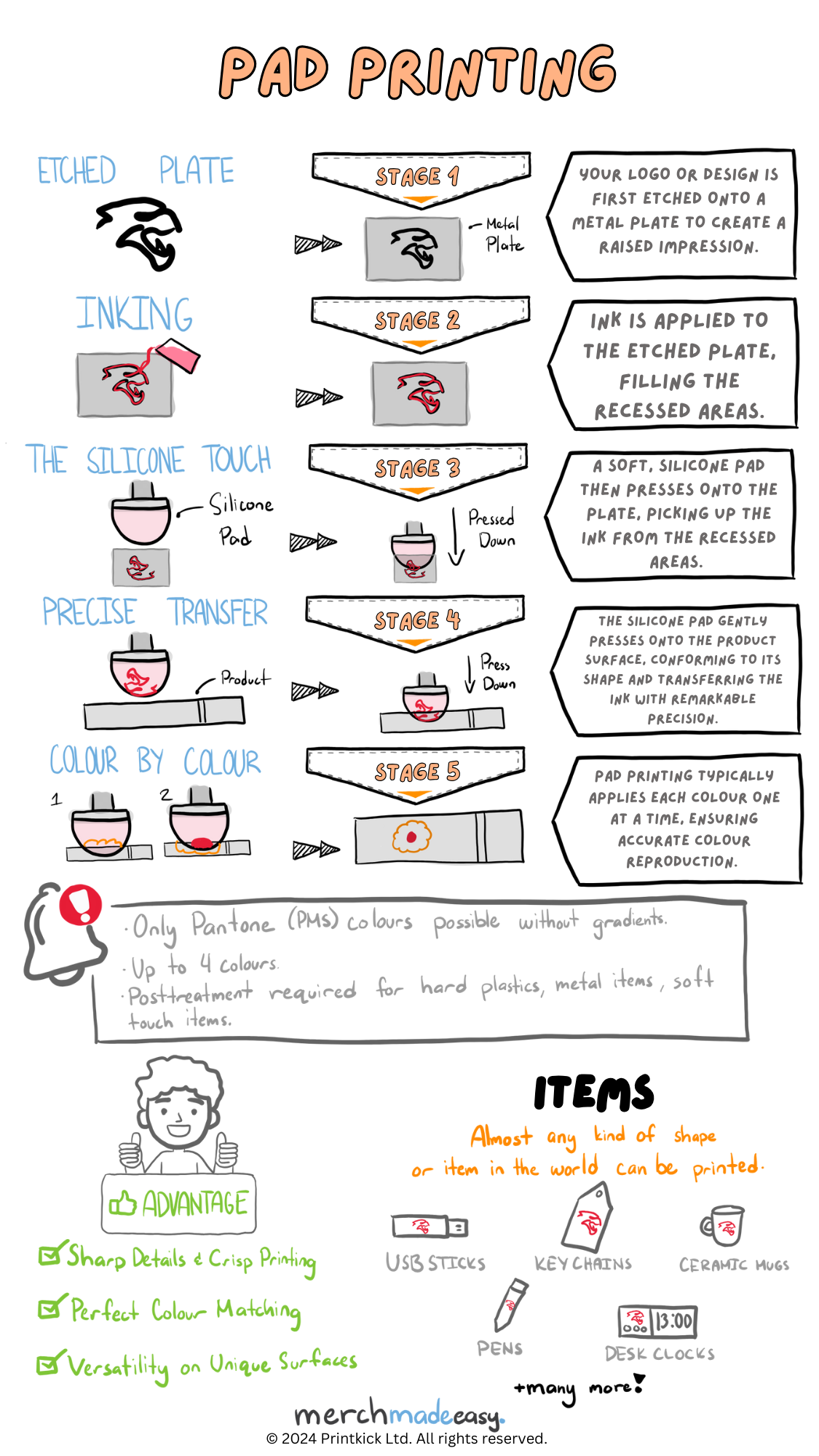

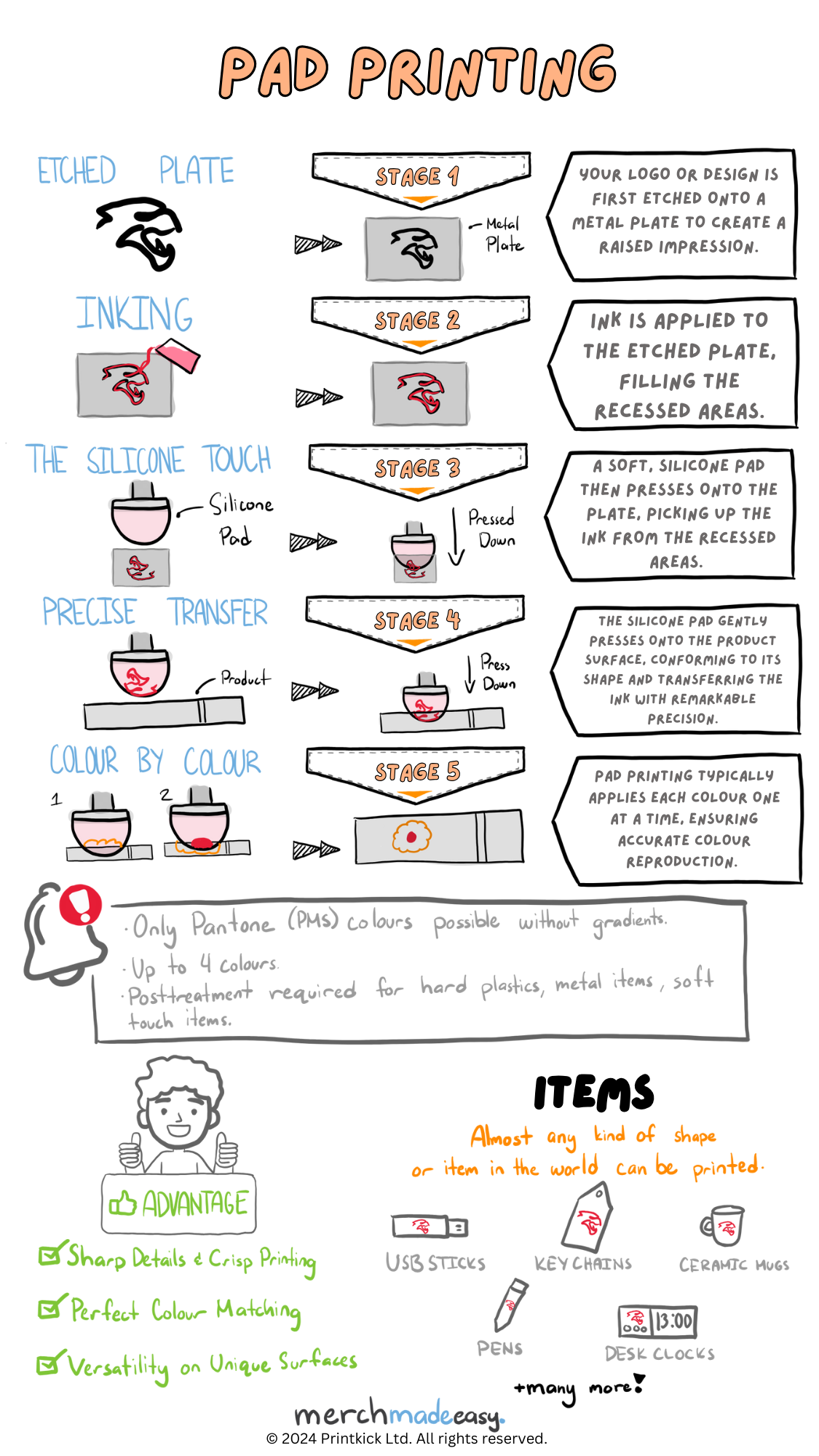

How Does Pad Printing Work?

Promo Store offers a comprehensive toolbox of printing techniques, and pad printing stands out for its ability to deliver exceptional detail and vibrant colours on unique or uneven surfaces

Imagine a printing technique that uses a soft, silicone pad to conform to even the most challenging surfaces. That's the beauty of pad printing! Here's a closer look:

- Etched Plate: Your logo or design is first etched onto a metal plate to create a raised impression.

- Inking: Ink is applied to the etched plate, filling the recessed areas.

- The Silicone Touch: A soft, silicone pad then presses onto the plate, picking up the ink from the recessed areas.

- Precise Transfer: The silicone pad gently presses onto the product surface, conforming to its shape and transferring the ink with remarkable precision

- Colour by Colour: Similar to screen printing, pad printing typically applies each colour one at a time, ensuring accurate colour reproduction.

Benefits of Pad Printing for Promo Merch:

- Sharp Details & Crisp Printing: Pad printing excels at producing intricate designs and logos with sharp edges, even on uneven or curved surfaces

- Perfect Colour Matching: Unlike some printing methods, pad printing allows for precise colour matching using the Pantone Matching System (PMS), ensuring your brand colours are flawlessly reproduced

- Versatility on Unique Surfaces: Pad printing shines on items with irregular shapes, curves, or textured surfaces, where other techniques might struggle. Think pens, golf balls, keychains, and more!